Unboxing Our Purillex PETG Square Media Bottles

Savillex Purillex PETG Square Media Bottles are an excellent choice for secure liquid media packaging. These heavy-duty PETG bottles with high-density polyethylene (HDPE) closures are recommended for storing liquid media, buffers, sera, or other materials. Designed for manual and automated fill lines, they are shatter-resistant and have exceptional gas barrier properties, high clarity, and molded graduation lines. Watch as Savillex Executive VP, Commercial Lisa Nash does an unboxing of Purillex PETG Square Media Bottles!

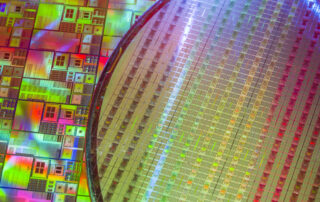

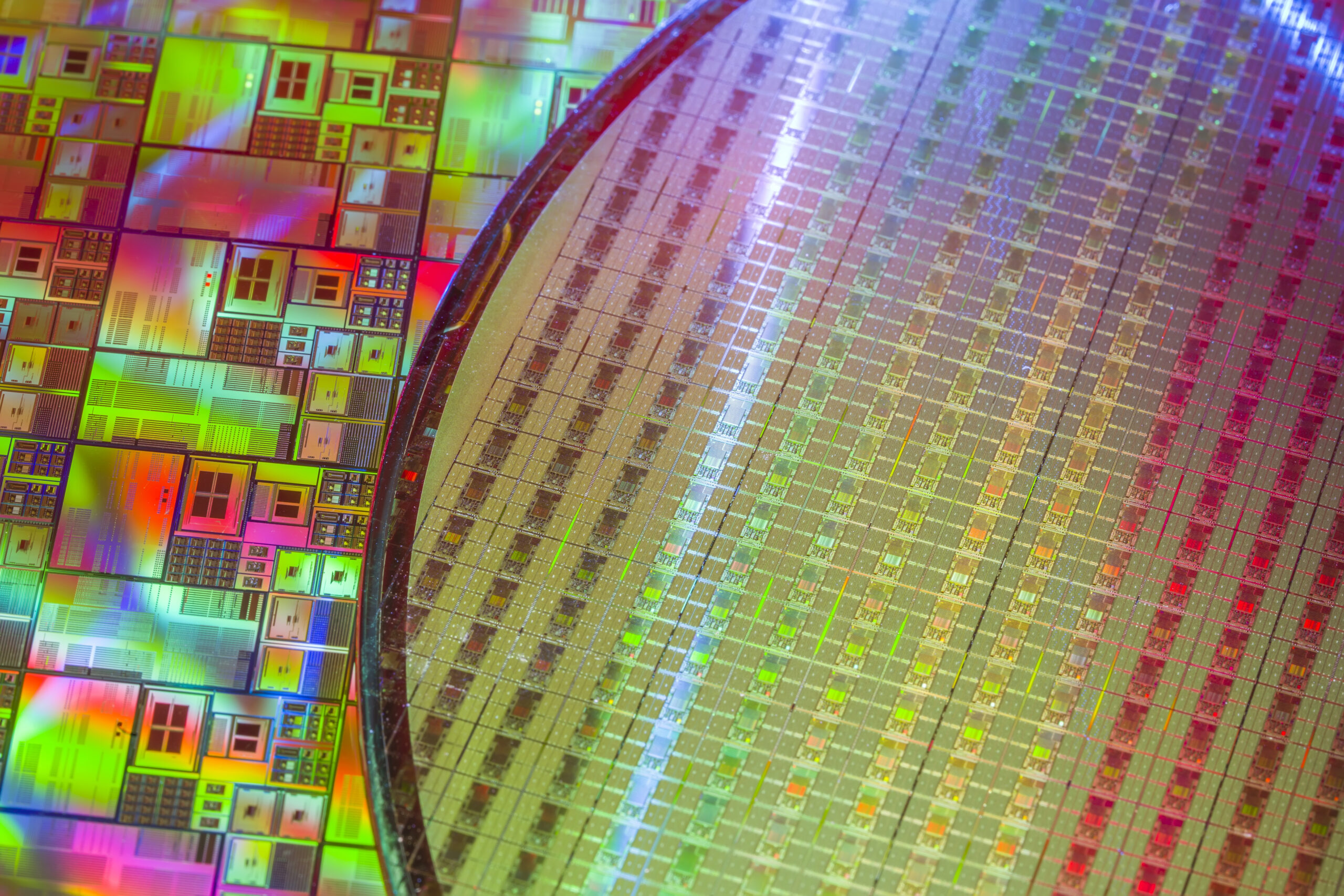

Success Story: Increasing Semiconductor Analysis Productivity with PFA Nebulizers

Success Story: Increasing Semiconductor Analysis Productivity with PFA Nebulizers Following up on our article from last week that discussed advancements in PFA nebulizer technology, here's a real life example of the key role that these tools can play in ensuring the quality and integrity of semiconductor products - while also

Advancements in PFA Nebulizer Technology

Advancements in PFA Nebulizer Technology - Enhancing Usability and Productivity in the Semiconductor Industry The demand for precision and efficiency is paramount in semiconductor manufacturing. Key instruments like Inductively Coupled Plasma Mass Spectrometers (ICP-MS) play a critical role in ensuring the quality and integrity of semiconductor products. A key element

A Comparative Study of PETG Polymer Versus Fluoropolymers

A Comparative Study of PETG Polymer Versus Fluoropolymers - Where Cost-Effectiveness and Sterilization Methods Matter Polyethylene Terephthalate Glycol (PETG), a versatile thermoplastic polymer, has cemented its position as a material of choice across a wide array of industries, owing to its remarkable attributes such as transparency, toughness, and ease of

Unraveling Genomic Mysteries Using PETG Bottles

Unraveling Genomic Mysteries Using PETG Bottles Genomics research demands precision, reliability, and integrity. And, amidst the myriad of tools and techniques utilized in this field, PETG (polyethylene terephthalate glycol) bottles emerge as unsung heroes, playing a pivotal role in preserving the integrity of genetic material and driving advancements in genomic

Getting Ready for Interphex 2024

Getting Ready for Interphex 2024 In the world of pharmaceutical manufacturing and biotechnology, few annual events draw the crowds, national attention, and wealth of knowledge that Interphex does. The show delivers on an expansive exhibition floor featuring exhibitors ranging from established industry leaders to hopeful startups, in addition to a

The Essential Role of PETG Bottles in Life Sciences and Research

The Essential Role of PETG Bottles in Life Sciences and Research The significance of proper storage and transportation of solutions in life sciences and research cannot be overstated. Among these, PETG (polyethylene terephthalate glycol) bottles have emerged as indispensable assets, playing a crucial role in maintaining the integrity of valuable

Unboxing Our Purillex PETG Square Media Bottles

Unboxing Our Purillex PETG Square Media Bottles About Purillex PETG® Square Media Bottles Savillex Purillex

Success Story: Increasing Semiconductor Analysis Productivity with PFA Nebulizers

Success Story: Increasing Semiconductor Analysis Productivity with PFA Nebulizers Following up on our article from

Advancements in PFA Nebulizer Technology

Advancements in PFA Nebulizer Technology - Enhancing Usability and Productivity in the Semiconductor Industry The

A Comparative Study of PETG Polymer Versus Fluoropolymers

A Comparative Study of PETG Polymer Versus Fluoropolymers - Where Cost-Effectiveness and Sterilization Methods Matter

Unraveling Genomic Mysteries Using PETG Bottles

Unraveling Genomic Mysteries Using PETG Bottles Genomics research demands precision, reliability, and integrity. And, amidst

Getting Ready for Interphex 2024

Getting Ready for Interphex 2024 In the world of pharmaceutical manufacturing and biotechnology, few annual