Purillex ETFE Bottles for Radiopharmaceutical Manufacturing

Radiopharmaceuticals are emerging as highly effective therapeutic and diagnostic agents for multiple diseases, including cancers, hyperthyroidism, and certain blood disorders. On the therapeutic front, they work by delivering radionuclides (radiation) to targeted cells, directly causing systematic and irreparable damage. As a diagnostic tool, they serve as an essential component of muclear medicine imaging – which helps provide a clear picture of how a patient’s tissues and organs are performing without harming the individual.

A Comparative Study of PETG Polymer Versus Fluoropolymers

A Comparative Study of PETG Polymer Versus Fluoropolymers - Where Cost-Effectiveness and Sterilization Methods Matter Polyethylene Terephthalate Glycol (PETG), a versatile thermoplastic polymer, has cemented its position as a material of choice across a wide array of industries, owing to its remarkable attributes such as transparency, toughness, and ease of

Unraveling Genomic Mysteries Using PETG Bottles

Unraveling Genomic Mysteries Using PETG Bottles Genomics research demands precision, reliability, and integrity. And, amidst the myriad of tools and techniques utilized in this field, PETG (polyethylene terephthalate glycol) bottles emerge as unsung heroes, playing a pivotal role in preserving the integrity of genetic material and driving advancements in genomic

Getting Ready for Interphex 2024

Getting Ready for Interphex 2024 In the world of pharmaceutical manufacturing and biotechnology, few annual events draw the crowds, national attention, and wealth of knowledge that Interphex does. The show delivers on an expansive exhibition floor featuring exhibitors ranging from established industry leaders to hopeful startups, in addition to a

The Essential Role of PETG Bottles in Life Sciences and Research

The Essential Role of PETG Bottles in Life Sciences and Research The significance of proper storage and transportation of solutions in life sciences and research cannot be overstated. Among these, PETG (polyethylene terephthalate glycol) bottles have emerged as indispensable assets, playing a crucial role in maintaining the integrity of valuable

Elevating Life Sciences Through Innovative Container Solutions

Elevating Life Sciences Through Innovative Container Solutions Within the world of life sciences, efficiency and safety reign supreme - and therefore, the role of packaging transcends mere containment. Imagine a world where every detail in the packaging of containers is meticulously designed to enhance operational flow, protect the integrity of

Make Your Mark: Laser Engraving on Scientific Products

Make Your Mark: Laser Engraving on Scientific Products In scientific settings, where precision, traceability, and reliability are paramount, laser engraving on fluoropolymer parts and products has become the norm. From tracking the manufacturing date of laboratory equipment to monitoring the usage of specific containers, laser engraving offers many benefits that

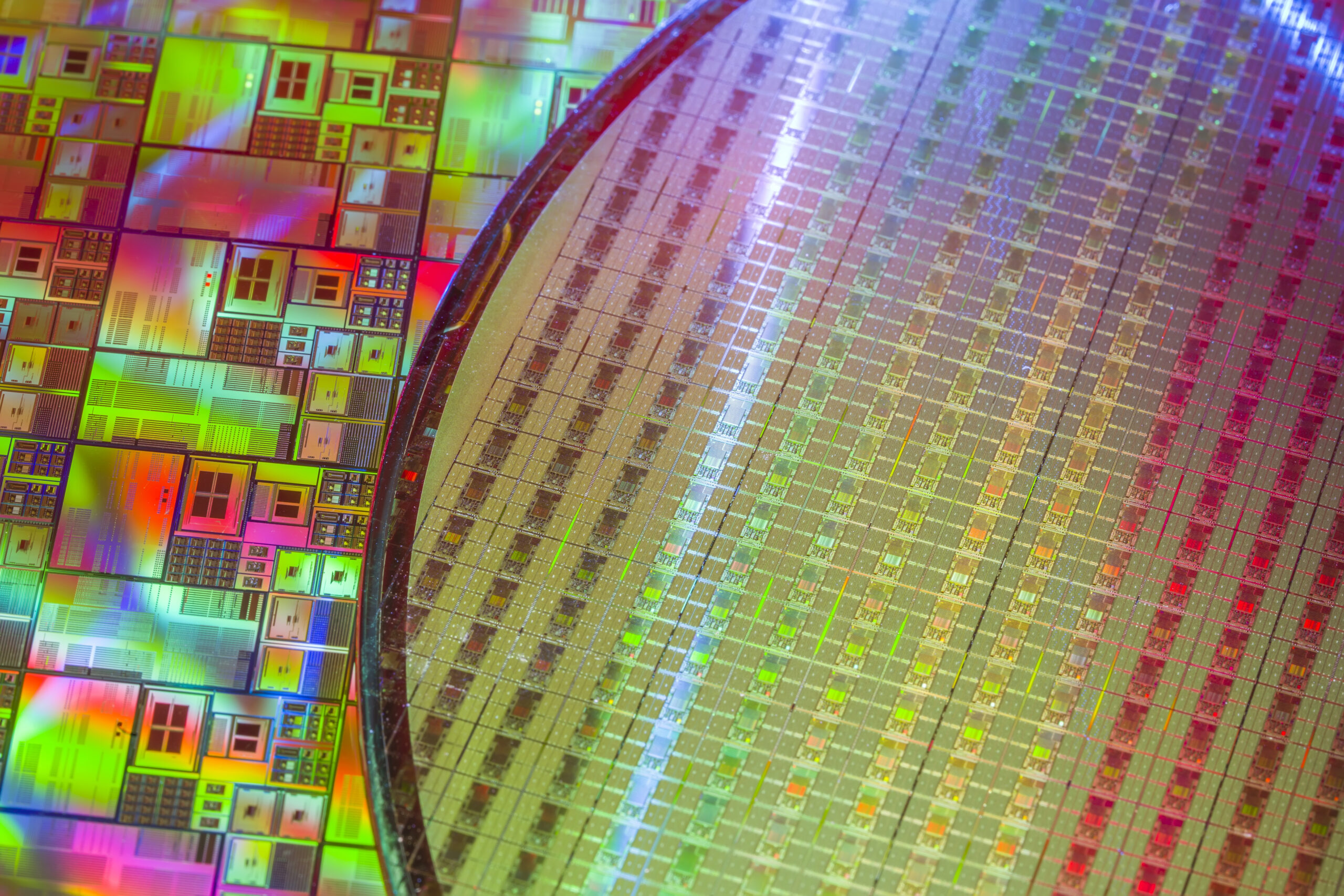

Advancements in PFA Nebulizer Technology

Advancements in PFA Nebulizer Technology - Enhancing Usability and Productivity in the Semiconductor Industry The

A Comparative Study of PETG Polymer Versus Fluoropolymers

A Comparative Study of PETG Polymer Versus Fluoropolymers - Where Cost-Effectiveness and Sterilization Methods Matter

Unraveling Genomic Mysteries Using PETG Bottles

Unraveling Genomic Mysteries Using PETG Bottles Genomics research demands precision, reliability, and integrity. And, amidst

Getting Ready for Interphex 2024

Getting Ready for Interphex 2024 In the world of pharmaceutical manufacturing and biotechnology, few annual

The Essential Role of PETG Bottles in Life Sciences and Research

The Essential Role of PETG Bottles in Life Sciences and Research The significance of proper

Elevating Life Sciences Through Innovative Container Solutions

Elevating Life Sciences Through Innovative Container Solutions Within the world of life sciences, efficiency and