Purillex ETFE Bottles for Radiopharmaceutical Manufacturing

Radiopharmaceuticals are emerging as highly effective therapeutic and diagnostic agents for multiple diseases, including cancers, hyperthyroidism, and certain blood disorders. On the therapeutic front, they work by delivering radionuclides (radiation) to targeted cells, directly causing systematic and irreparable damage. As a diagnostic tool, they serve as an essential component of muclear medicine imaging – which helps provide a clear picture of how a patient’s tissues and organs are performing without harming the individual.

New Technologies Demand Different Thinking. Can Bioprocess Evolve?

Can Bioprocessing Evolve to Meet a Rapidly Changing World? It’s a brave new world for the bioprocessing industry as groundbreaking new technologies - like cellular therapies and mRNA vaccines - emerge and hit the market at a blinding pace. However, behind every one of these technological triumphs is complex manufacturing

Phacilitate Advanced Therapies Week 2022 Recap

By Drew Carlson, Applications Development Manager – Life Sciences Conversations and Collaboration Advanced Therapies Week, organized by Phacilitate, certainly gets a gold star from many attendees regarding their chosen location of Miami Beach. The warm weather is a welcome bonus in the heart of winter for many of the 300+

Bioprocess production and supply in pandemic times

The bioprocess industry isn’t immune to supply chain challenges These pandemic times have stretched global supply chains to their breaking point. And as a result, the bioprocess industry has been attempting to overcome several major hurdles. Chief among them is a shortage in key components like piping, filters, diaphragms and

Profiling fluoropolymer bottle extractables

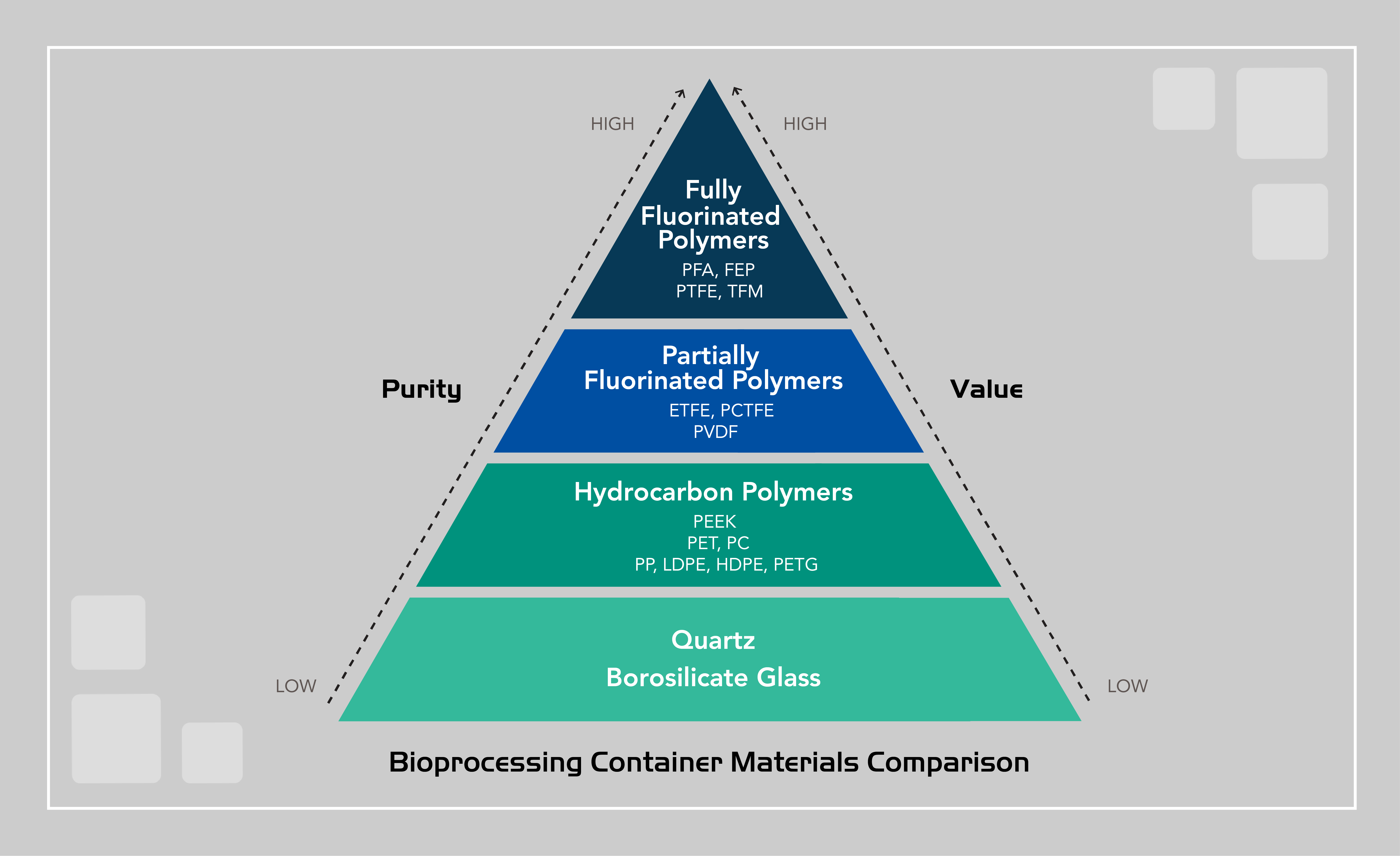

Understanding the impact of container extractables When choosing containers for applications such as critical drug substances, cell therapies and regenerative medicines, it’s important to consider the effect extractables can have on products. Extractables are the organic or inorganic chemical compounds released from container systems when faced with aggressive laboratory conditions

Getting “Closure” on Bottle Torque and Seal Integrity

Balancing Container Integrity and Closure Torque Applications like cell therapies and regenerative medicines demand absolute container integrity to ensure product sterility. To that end, bottles, vials, sample jars, and other rigid containers tend to be the natural choice due to their durable construction and strong closure systems. However, another key

Interphex 2021 Recap

By Eric Isberg, VP of Life Sciences Obsvervations and Trends of Interphex 2021 We attended Interphex in NYC as our second live show of the 2021 season. Interphex remains the “who’s who” in the bioprocessing world, with over 500 exhibitors and thousands of attendees. Although a noticeably quieter show than

What’s the Issue? This Is the Best Container for Tissues.

The Case for Jars in Tissue Processing In tissue processing and transplantation, tissue engineering, and

New Technologies Demand Different Thinking. Can Bioprocess Evolve?

Can Bioprocessing Evolve to Meet a Rapidly Changing World? It’s a brave new world for

Phacilitate Advanced Therapies Week 2022 Recap

By Drew Carlson, Applications Development Manager – Life Sciences Conversations and Collaboration Advanced Therapies Week,

Bioprocess production and supply in pandemic times

The bioprocess industry isn’t immune to supply chain challenges These pandemic times have stretched global

Profiling fluoropolymer bottle extractables

Understanding the impact of container extractables When choosing containers for applications such as critical drug

Getting “Closure” on Bottle Torque and Seal Integrity

Balancing Container Integrity and Closure Torque Applications like cell therapies and regenerative medicines demand absolute