Purillex ETFE Bottles for Radiopharmaceutical Manufacturing

Radiopharmaceuticals are emerging as highly effective therapeutic and diagnostic agents for multiple diseases, including cancers, hyperthyroidism, and certain blood disorders. On the therapeutic front, they work by delivering radionuclides (radiation) to targeted cells, directly causing systematic and irreparable damage. As a diagnostic tool, they serve as an essential component of muclear medicine imaging – which helps provide a clear picture of how a patient’s tissues and organs are performing without harming the individual.

BDS and Single-Use Technology Pain Points

Single-Use Technologies and BDS: a Fragile Relationship To successfully store and ship high-value bulk drug substances (BDS), you need materials that are durable, stable at low temperatures, chemically compatible and pure. So, how is that accomplished? A few of the mainstay materials include stainless steel cans, as well as PETG

Creating Fluoropolymer Parts for Aerospace

Fluoropolymers to the Flight Deck! In our last blog, we talked about the growing demand for fluoropolymers in aerospace and where they would fit best on today’s lighter, more efficient passenger aircraft. Here, we’ll dive in to how we began working with a leading aerospace manufacturer to create custom PFA

Taking Flight with Fluoropolymers

Can Fluoropolymers Take Flight in Aerospace? Fluoropolymers have a firmly established place in the lab, but what about in the air? Or – to be more specific – on a modern passenger plane? Let’s dig a little deeper and find out whether or not fluoropolymers are flight worthy. First off,

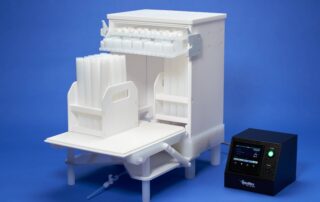

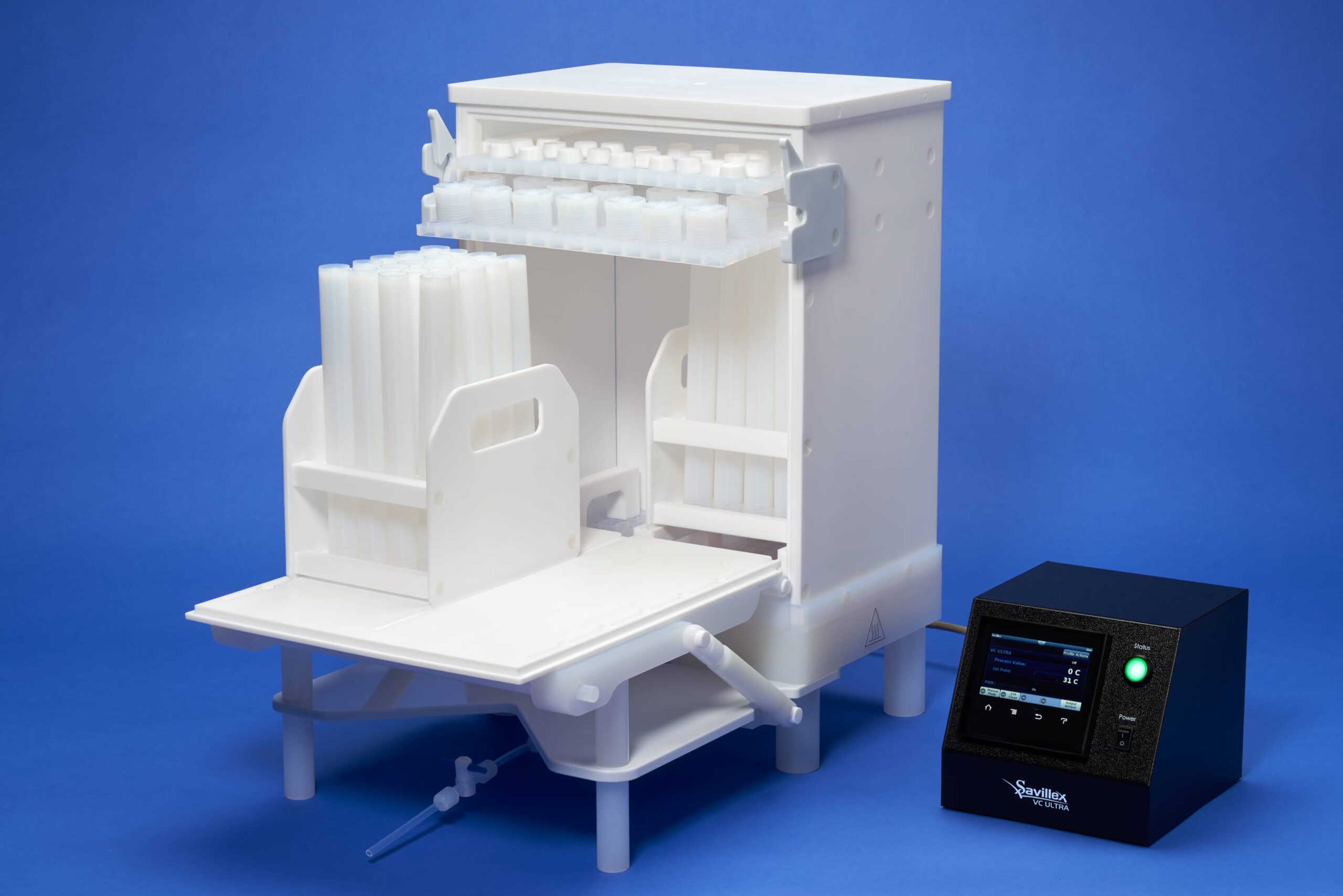

Meet the VC Ultra Acid Vapor Cleaning System

VC Ultra shown with vessel cleaning racks. Acid cleaning made easier – with the right tools Last time around, we talked about all the ways acid vapor cleaning systems provide a safer, more cost efficient and effective way to thoroughly acid clean microwave digestion vessels and other labware

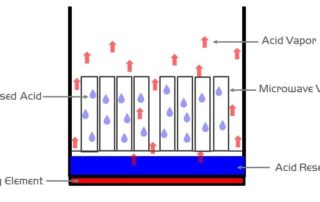

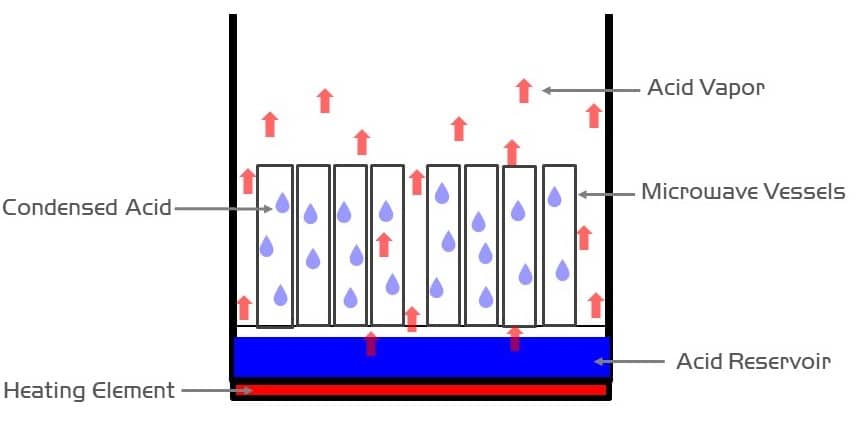

The Steamy Truth of Acid Vapor Cleaning

To Steam or Not to Steam Your Microwave Digestion Vessels Basic Acid Vapor Cleaning Concept Acid cleaning microwave digestion vessels is a critical step towards controlling contamination in the process of trace

Solving Problems Through Improved Tool Design

Injection molding depends on good tool design Savillex tooling and PFA parts example. Many details need to be considered when developing and manufacturing an injection molded product. You can have a great product idea and the right materials, but small flaws in your injection molding tool design could

Unique, High Purity, Gamma-Stable Solution for Low Temperature BDS Storage

ETFE Bottle and Vial Family Gamma Stable Game-Changer Last time, we talked about

BDS and Single-Use Technology Pain Points

Single-Use Technologies and BDS: a Fragile Relationship To successfully store and ship high-value bulk drug

Creating Fluoropolymer Parts for Aerospace

Fluoropolymers to the Flight Deck! In our last blog, we talked about the growing demand

Taking Flight with Fluoropolymers

Can Fluoropolymers Take Flight in Aerospace? Fluoropolymers have a firmly established place in the lab,

Meet the VC Ultra Acid Vapor Cleaning System

VC Ultra shown with vessel cleaning racks. Acid cleaning made easier – with

The Steamy Truth of Acid Vapor Cleaning

To Steam or Not to Steam Your Microwave Digestion Vessels