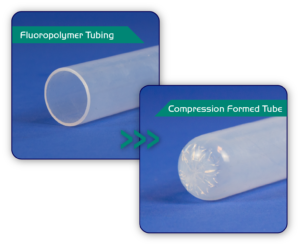

The challenge: Forming thin-walled tubes and liners from fluoropolymers

The challenge: Forming thin-walled tubes and liners from fluoropolymers

Fluoropolymers are well known for their wide temperature range, freedom from trace metal contamination and chemical resistance. It’s these properties that make fluoropolymers ideal for use as test tubes or liners in the high-temperature digestion of solid materials with aggressive reagents – such as concentrated mineral acids.

Fluoropolymers, however, are very difficult to mold in thin-walled sections and in long, tube-like shapes. In response, Savillex has developed a new Compression Forming Technology that enables the manufacture of thin-walled fluoropolymer closed-end tubes. End tube configurations can be in the form of a rounded test tube shape, conical shape, flat end, or other custom designs.

New Compression Forming Technology helps cut manufacturing costs

Up until now, tube shapes needed to be injection molded, then machined to the required wall thickness. In many cases, this method of manufacturing was cost prohibitive. Compression Forming Technology enables closed end tubes to be fabricated from stock fluoropolymer tubing in one step – keeping the cost of the tube low.

Where can compression-formed fluoropolymer products be used?

Applications for these new, compression-formed fluoropolymer products include microwave digestion liners, block digestion tubes for acid digestion, disposable tube liners, or any other application for closed end tubes where very low or high temperature resistance (-200oC to 260oC), freedom from trace metals or chemical inertness is required.

Available tube volumes are based on standard sizing and range from around 10 mL to 100 mL. Savillex can also design and fabricate custom tubes to customer requirements.

Get a closer look at our full suite of custom capabilities for your next project.