The Problems With Traditional Life Sciences Containers (Part One)

In the world of life sciences and medical research, containers play a crucial role in the storage, transportation, and preservation of various materials. These containers are used to store chemicals, biological samples, and other sensitive substances.

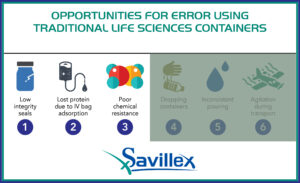

However, like any other aspect of scientific research, there are unique challenges associated with life sciences containers – many of which lead to an increased chance of error during crucial workflows. For one, these errors can lead to inaccurate data, rendering experiments and research findings unreliable. They can also create a hazardous or potentially unsafe environment, and can have a negative financial impact on the organizations that use them.

But what are the specific common problems that you should be on the lookout for when putting bottles, jars, vials, bags, and other life sciences containers into use? In this two-part blog series, we will discuss some of these challenges and explore potential solutions.

Keep an eye out for these potential pitfalls during your life sciences applications.

In part one of this blog series we will examine three of the six primary errors associated with the use of many life sciences containers on the market today. Our Purillex® line of Bottles, Jars, and Vials were designed with life sciences applications specifically in mind, and with the goal to greatly reduce or even eliminate these errors. Let’s get into the first three so we can gain a better idea of what to look out for.

1) Low Integrity Seals

Container seal integrity is a crucial element of quality control for many life sciences applications, including cell therapy and bulk drug storage. Compromised seals not only jeopardize sterility, but can also lead to contamination of contents. Other troublesome issues this could create include:

- Container leakage

- An unsafe working environment

- Jeopardized sample quality

- Jeopardized regulatory compliance

Our Purillex containers are excellent choices for life sciences applications thanks in large part to their robust closure systems. In fact, the results of a Container Closure Integrity Testing (CCIT) validation study indicated that Purillex bottles torqued to 17.5 ± 0.1 inch-pound or higher yielded helium leak rates below the acceptance limit.

2) Lost Protein Due to IV Bag Adsorption

Multiple studies, including this one found in the National Library of Medicine, explain the impact that leachables from saline-containing IV bags can have on therapeutic protein properties. This can result in inadequate execution of therapies and insufficient results.

Polyethylene bags can adsorb proteins to some extent, but they are not as protein-resistant as certain fluoropolymer materials. Polyethylene is a relatively hydrophobic material and can interact with proteins through non-specific hydrophobic interactions. This can lead to protein adsorption, which may result in sample loss and changes in protein conformation.

PFA (perfluoroalkoxy), on the other hand, is a highly inert material that minimizes protein adsorption. It doesn’t interact significantly with proteins, helping to maintain the integrity of the sample. Purillex Bottles, Jars, and Vials are all manufactured with high-quality PFA to help avoid this issue.

3) Poor Chemical Resistance

Chemically resistant containers are essential components of an efficient and safe laboratory environment. While these containers should be designed to be resistant to a wide range of chemicals and solvents, many fall short – causing inefficiencies during important scientific applications and in many cases unusable samples.

This is especially important in research laboratories, where a wide variety of reagents, chemicals and other substances are regularly handled and stored. The risk of cross-contamination is already at a much higher level in these settings and using anything less that the highest quality fluoropolymer containers is essentially a recipe for disaster.

Our Purillex containers are made with PFA, which, in addition to having the widest working temperature range of any fluoropolymer, is inert and non-reactive with virtually every chemical used in life science applications. They are designed to help avoid product adulteration due to chemical contamination, and lack of chemical stability (particularly with acids, bases, and solvents). Purillex containers are the only fluoropolymer containers specifically designed for life science applications.

A side note about temperature resistance…

PFA has excellent low-temperature resistance, making It a good choice for freeze-thaw applications. Because it maintains its mechanical properties and chemical resistance over a wide temperature range, from very low temperatures to very high temperatures, it is a great choice for bulk drug storage and stability testing. See this study for more information.

In conclusion, life sciences containers present unique challenges due to the nature of their contents and the stringent requirements for their storage and transportation. By addressing issues related to contamination, temperature control, durability, and organization, researchers and manufacturers can overcome these challenges and ensure the best possible outcomes in life sciences research. Harnessing innovative technologies and implementing robust protocols will pave the way for safer and more efficient container management in the field of life sciences.

Part two of this blog series is coming soon!

Click here to learn more about our Purillex line of life sciences containers including Bottles, Jars, and Vials.