Fusion Welding with Fluoropolymers: Building Stronger Bonds

Fusion Welding with Fluoropolymers: Building Stronger Bonds

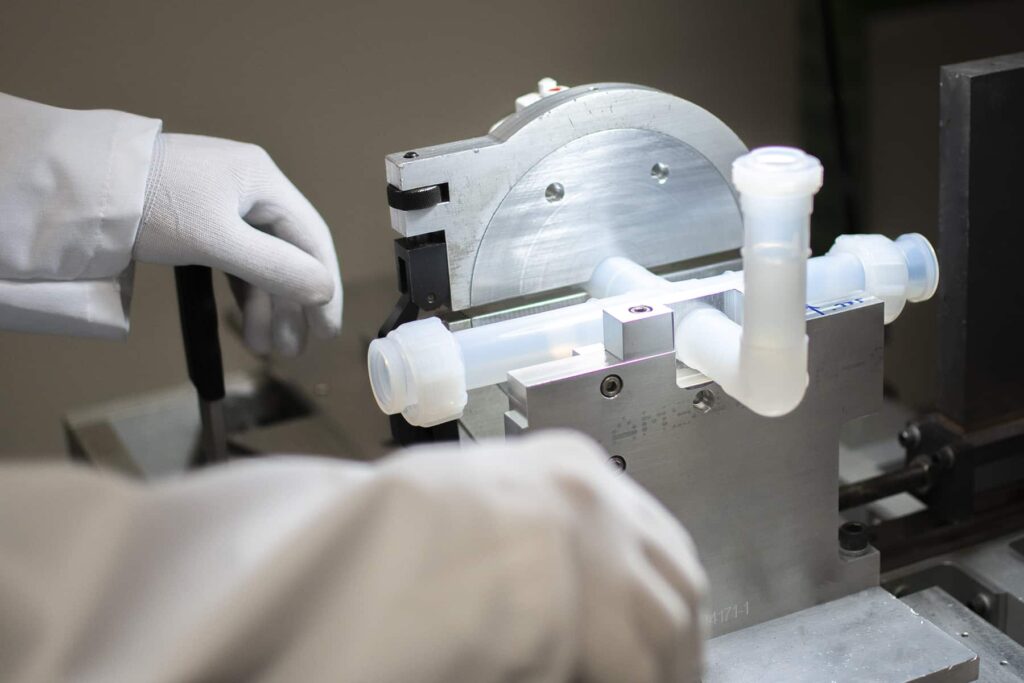

Typically, the weakest parts (and most likely failure points) of any custom assembly are the welded joints. But with fusion welding, that’s not the case.

Savillex has developed proprietary, non-contact fusion welding equipment and techniques that can be used to build stronger, high-purity fluoropolymer assemblies. The fusion welding process results in a welded joint that’s actually stronger than the original parts.

Other methods like contact welding, for example, involve melting parts together in direct contact with a heater or welding rod – but these processes are not clean enough for assemblies that are to be used in transporting ultra-pure liquids or gasses.

Fusion welding is non-contact, meaning there is virtually zero risk of introducing any outside contamination to fluoropolymer parts used in high purity applications.

Fusion Welding as Part of a Custom Assembly Service

Savillex offers fusion welding services for the semiconductor, pharmaceutical, chemical processing and medical industries. With our proprietary equipment, we can weld fluoropolymer parts as small in diameter as .094 in (2.4 mm) and as large as 8 in (20.3 cm).

When it comes to fabricating custom assemblies, Savillex makes the process seamless (pun intended) from start to finish. We work directly with customers to understand their requirements and engineer a design

From there, we can source all the necessary components and supply finished, fusion welded assemblies that have been autoclave sterilized and packaged in a Class 7 cleanroom.

Customers can also tap into Savillex’s injection molding capabilities if they require custom fluoropolymer parts for an assembly.

Have a specific assembly project that you would like to discuss? Drop us a line and we’ll get back to you.