Fluoropolymer pressure vessels provide clean chemical transport

Fluoropolymer pressure vessels provide clean chemical transport

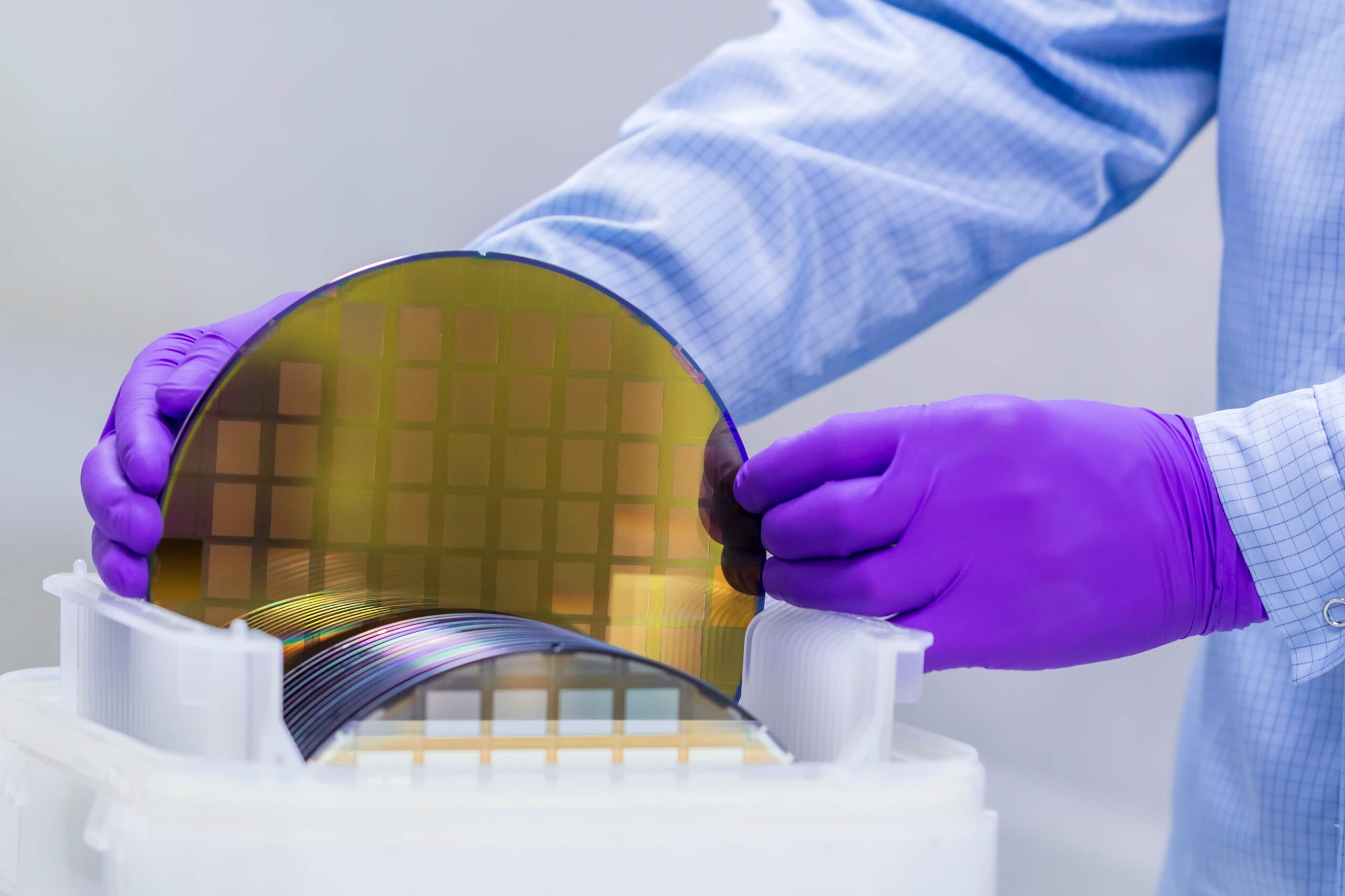

A wide range of aggressive chemicals are used in wafer processing. And since these chemicals are in direct contact with the wafer surface, they need to be as free from trace metal contamination as possible.

While conventional pumps are still used for some applications, the cleanest method for delivering chemicals is by gas displacement using pressure vessels made from PFA.

These PFA vessels are filled with chemicals and pressurized. This pressure then delivers the chemical to the wafer processing tool. Unlike pumps, there are no moving parts, which helps avoid potential downtime, lost product and the very high costs associated with a pump failure.

Only high purity PFA is in contact with the chemical, so contamination risk is virtually eliminated.

While pressure vessels can also be manufactured from PTFE, high purity PFA resin has lower trace metal content than PTFE, and the manufacturing process used to make PFA vessels is much cleaner.

Savillex has the capability to custom manufacture PFA pressure vessels in specific lengths or volumes (up to a four-liter capacity and eight-inch diameter) – and with a variety of optional end cap fittings.

Now, we’ll dig a little into how our pressure vessel manufacturing capabilities set us apart from the rest.

Pressure vessel production at the speed of the semiconductor industry

The semiconductor industry moves quickly – but so do we.

A decided advantage to our pressure vessel manufacturing process is that we have the ability to be highly responsive and can deliver finished products within a relatively short turnaround time.

Why is this so important? Semiconductor fabs simply can’t afford long spells of down time when components fail. As well, when fabs want to expand and add production lines to meet higher demand, we can supply them with custom pressure vessel components on time and to the exact specifications required.

In addition, Savillex can produce larger-capacity pressure vessel containers while remaining completely clean throughout the process.

Most manufacturers, when creating pressure vessels that exceed a diameter of three to four inches, must rely on creating components via rotational molding. This is an inherently less clean process that has a greater potential to introduce contamination.

However – using our proprietary, non-contact fusion welding techniques, Savillex can maintain high purity while building ultra-durable pressure vessel assemblies up to eight inches in diameter.

Since we’re talking about all things pressure vessels – why not get more info on our lineup of custom pressure vessels? You also may want to explore more about our full range of custom engineered solutions and capabilities for your next assembly.