Advancements in PFA Nebulizer Technology – Enhancing Usability and Productivity in the Semiconductor Industry

The demand for precision and efficiency is paramount in semiconductor manufacturing. Key instruments like Inductively Coupled Plasma Mass Spectrometers (ICP-MS) play a critical role in ensuring the quality and integrity of semiconductor products.

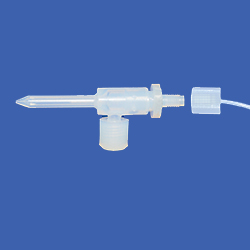

A key element of the ICP-MS equation is the nebulizer, which is used to generate aerosol from a liquid sample. The aerosol passes into the plasma where it is atomized and ionized. The ions then pass into the ICP-MS for analysis.

Over the years, nebulizers made with PFA, or perfluoroalkoxy alkane, have become indispensable due to their inertness to various chemical processes and high efficiency. However, despite their advantages over traditional glass nebulizers, early designs of PFA nebulizers presented certain limitations, particularly in terms of lifespan and troubleshooting efficiency.

While revolutionary, the initial generation of PFA nebulizers encountered drawbacks that hindered their widespread adoption. One of the primary concerns was their relatively shorter lifespan, typically lasting just a few months compared to the more durable glass nebulizers, which could endure for a year or more.

Additionally, the fixed uptake line configuration posed challenges in troubleshooting and maintenance. Identifying the source of issues such as high elemental background was complex, as operators couldn’t ascertain whether it stemmed from the uptake line, autosampler probe, or the nebulizer itself. This led to a downtime for ICP-MS tools, impacting productivity and efficiency for semiconductor manufacturers.

A breakthrough emerged with the introduction of a new PFA nebulizer design. This innovative solution revolutionized the landscape of PFA nebulizer technology. The distinguishing feature lies in incorporating a demountable uptake line while retaining the high sensitivity characteristic of conventional fixed-uptake line nebulizers. Central to its design is a novel zero-dead volume connector on the uptake line, facilitating rapid sample washout equivalent to fixed-uptake line nebulizers.

With the advent of the demountable uptake line nebulizer, the innovation marked a significant leap in usability and productivity for semiconductor manufacturers. Unlike its predecessors, the new design offers unprecedented flexibility in troubleshooting and maintenance.

Operators can swiftly interchange the uptake line and probe for inspection when elevated background signals occur, potentially attributed to sample carryover or damaged autosampler probes. This eliminates the need to replace the nebulizer and subsequent requalification of nebulizers, thereby minimizing downtime and optimizing operational efficiency.

Furthermore, in cases where the nebulizer body is suspected to be the source of the problem, it can be replaced independently without necessitating changes to the uptake line or probe. This streamlined approach saves valuable time and resources that would otherwise be expended on cleaning and recalibrating a new uptake line.

Overall, the evolution of PFA nebulizer technology and the introduction of demountable uptake line nebulizers represent a paradigm shift towards greater usability and productivity. By addressing longstanding challenges associated with maintenance and troubleshooting, these advancements empower semiconductor manufacturers to uphold stringent quality standards while maximizing operational efficiency.

As the semiconductor landscape continues to evolve, innovations in instrumentation technology will undoubtedly play a pivotal role in driving progress and innovation across the industry.

Are you looking to enhance efficiency and usability in your semiconductor manufacturing process? Upgrade to the Savillex s-Type PFA Nebulizer with its innovative demountable uptake line design to experience unparalleled flexibility and productivity in your ICP-MS.

Click here to learn more about Savillex PFA Nebulizers or feel free to contact us at info@savillex.com with any questions!